Acrylic lens, PMMA Plastic lens.

Lens sumo:

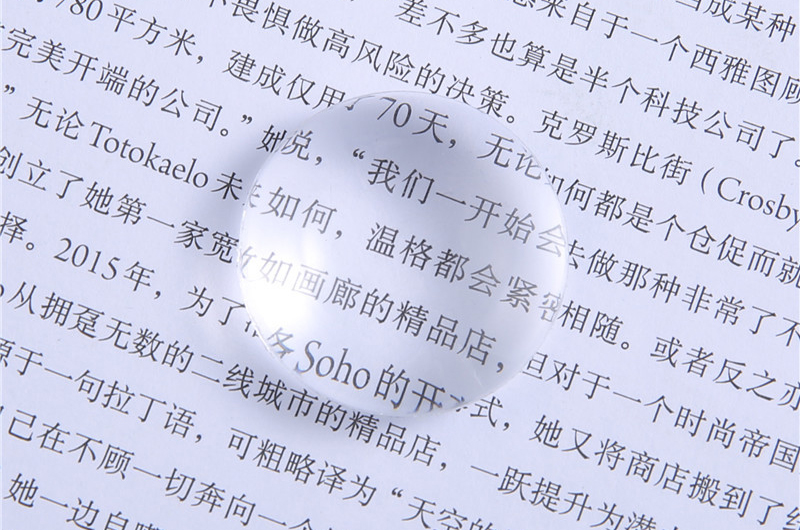

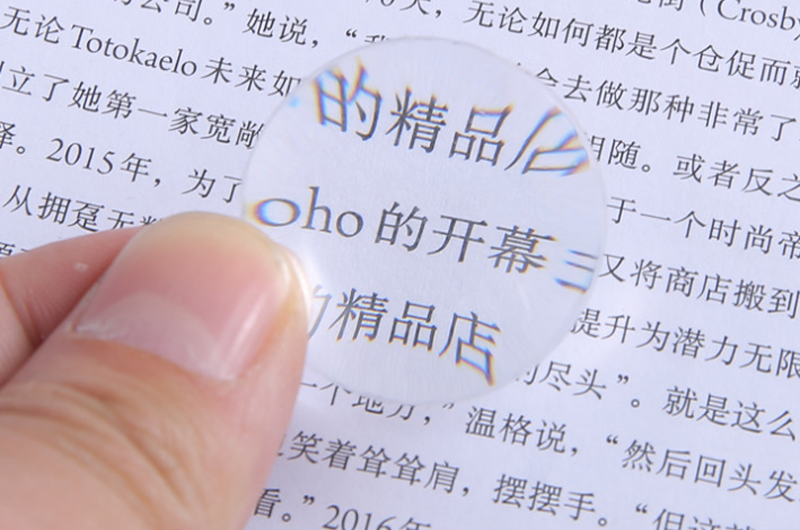

Iyo base plate ye acrylic lens yakagadzirwa nePMMA, iyo inonzi zvakare yakadzvanywa acrylic lens nevanhu vekuHong Kong neTaiwan.Acrylic lens inoreva iyo extruded acrylic plate.Kuti uwane iyo optical giredhi electroplating, base ndiro inoumba girazi mhedzisiro mushure mekuputira vacuum.Lens yepurasitiki inoshandiswa kutsiva girazi regirazi, iro rine zvakanakira uremu huremu, zvisiri nyore kutyora, zviri nyore kuumba uye kugadzirisa, kuvepa kwemavara uye zvichingodaro, Kukura kwekusimudzira kuri kuwedzera zuva nezuva, uye yave rudzi rwehunyanzvi. mukugadzira lens.Plastic plates anowanzo gadzirwa kuita: single-sided mirror, double-sided mirror, plastic mirror, paper mirror, half lens, etc. anogona kugadzirwa zvichienderana nezvinodiwa zvakasiyana.Semuenzaniso, chidzitiro chenhare mbozha neTV chinogona kuonekwa zuva nezuva.

Lens maitiro:

Acrylic inokodzera kushandiswa kwechipiri, senge machining, thermoplastic molding, blow molding, blister, solvent bonding, thermal printing, screen printing uye vacuum electroplating.Mushure mekubudirira, ndiyo yatinodaidza kuti acrylic lens.

Acrylic plate ine polymerized nemethyl methacrylate monomer (MMA), iyo polymethylmethacrylate (PMMA) ndiro plexiglass, inova imhando yeplexiglass inogadziriswa nemaitiro akakosha.Iyo ine mukurumbira we "plastiki Mambokadzi".Tsvagiridzo uye kuvandudzwa kwe acrylic ine nhoroondo yemakore anopfuura zana.

Kushandisa lens:

Acrylic ine zvakanakira uremu huremu, mutengo wakaderera uye nyore kuumba.Maitiro ayo ekuumba anosanganisira kukanda, jekiseni kuumba, machining, acrylic thermoforming, etc. Kunyanya, jekiseni molding inogona kugadzirwa muhuwandu hukuru, nemaitiro ari nyore uye mutengo wakaderera.Nokudaro, inoshandiswa zvakanyanya muzvikamu zvezviridzwa, marambi emotokari, optical lenses, mapaipi akajeka uye zvichingodaro.

Acrylic ndiyo yakanakisa zvinhu zvitsva kugadzira hutsanana ware mushure me ceramics.Kuenzaniswa neyakajairwa ceramic zvinhu, acrylic haina kungoita isingaenzaniswi kupenya kwepamusoro, asiwo ine zvinotevera zvakanakira: kusimba kwakanaka uye kwete nyore kukuvadza;Kudzoreredza kwakasimba, chero furo rakapfava rakanyikwa mumushonga wemazino rinogona kupukuta hutsanana hutsva.Mamiriro acho akapfava, uye hapana bhonzo rinotonhorera rinonzwa munguva yechando;Mavara akajeka anogona kusangana nekutsvagirwa kwega kwega kwekunaka kwakasiyana.Iyo tafura bheseni, bhavhu uye chimbuzi chakaitwa ne acrylic haisi chete yakanakisa muchimiro, yakasimba, asi zvakare ine hushamwari kwezvakatipoteredza.Mutsara wayo wemwaranzi wakada kufanana neemapfupa evanhu.Acrylic sanitary ware yakatanga kuoneka muUnited States uye ikozvino inodarika 70% yemusika wese wepasirese.Nekuda kwekuoma uye kudhura kwakanyanya kwekugadzirwa kwe acrylic, kune akawanda anodhura anotsiva mumusika.Aya anotsiva, anozivikanwawo se "acrylic", anongori akajairwa organic board kana composite board (inozivikanwawo sesandwich board).Ordinary organic board inokandwa neyakajairika plexiglass inotsemuka zvinhu uye pigment.Kuoma kwayo kwepamusoro kwakadzikira uye kuri nyore kupera.Mhedzisiro yekupenya haina kunaka mushure mekupenya nejecha rakanaka.Iyo composite board ine chete yakatetepa layer ye acrylic pamusoro uye ABS plastiki pakati.Zviri nyore kudzikisa nekuda kwesimba rekuwedzera kwekupisa uye kutonhora kuderera mukushandisa.Yechokwadi uye yenhema acrylic inogona kucherechedzwa kubva kune yakavanzika mutsauko wemuvara uye kupurisa mhedzisiro yechikamu cheplate.1 Architectural application: hwindo, musuwo usingapindi ruzha uye hwindo, chivharo chekuvhenekera masikati, furati yefoni, girazi rekushongedza, etc Kushambadzira Chikumbiro: bhokisi rakareruka, signboard, signboard, show rack, etc Chifambiso chekufambisa: chitima, girazi rekudzosera mota, lenzi yemota, nezvimwe. 4 Chikumbiro chekurapa: incubator yemwana, midziyo yekuvhiya yakasiyana-siyana, zvinyorwa zvechivanhu: mabasa emaoko, magirazi ekuzora, mabhuraketi, aquariums, magirazi ematoyi, etc. Chishandiso cheindasitiri: mudziyo wepaneru uye chivharo, etc. reflector, acrylic reflector, nezvimwewo.

Maitiro maitiro:

1. Acrylic ine polar side methyl, iyo ine hygroscopicity iri pachena.Kunyura kwemvura kunowanzo 0.3% - 0.4%.Inofanira kunge iri acrylic ndiro isati yagadzirwa

Inofanira kuomeswa pasi pemamiriro e80 ℃ - 85 ℃ kwe4-5h.2. Acrylic ine maitiro anoshanda uye akajeka asiri eNewtonian fluid mumhando yekushisa yekuumbwa kwekugadzira.Iyo yakanyunguduka viscosity inoderera zvakanyanya nekuwedzera kweshear rate, uye iyo melt viscosity zvakare inotarisisa shanduko yekushisa.Naizvozvo, pakugadzirisa kuumbwa kwepolymethylmethacrylate, kuwedzera kuumbwa kwekumanikidza uye tembiricha zvinogona kuderedza zvakanyanya kunyunguduka viscosity uye kuwana fluidity iri nani.3. Tembiricha iyo acrylic inotanga kuyerera ingangoita 160 ℃, uye tembiricha painozotanga kuora inodarika 270 ℃, ine tembiricha yakakura yekugadzirisa.4. The viscosity ye acrylic melt yakakwirira, chiyero chekutonhora chinokurumidza, uye zvigadzirwa zviri nyore kubudisa kushushikana kwemukati.Naizvozvo, mamiriro ekuita anodzorwa zvakanyanya panguva yekuumbwa, uye zvigadzirwa zvinodawo mushure mekurapa mushure mekuumbwa.5. Acrylic inonzi amorphous polymer ine shrinkage duku uye kusiyana kwayo, kazhinji inenge 0.5% - 0.8%, iyo inobatsira pakugadzira zvikamu zvepurasitiki nehupamhi hwepamusoro.6. Acrylic cutting performance yakanaka kwazvo, uye chimiro chayo chinogona kugadzirwa nyore nyore mumhando dzakasiyana-siyana dzinodiwa.

Processing tekinoroji:

Acrylic inogona kutora kukanda, kuumba jekiseni, extrusion, thermoforming, laser engraving, laser yekucheka uye mamwe maitiro.

Kukandira kuumba

Casting molding inoshandiswa kugadzira maprofile senge plexiglass mahwendefa nemabhawa, kureva kuti, maprofile anoumbwa nehuwandu hwepolymerization.Zvigadzirwa zvakakandwa zvinoda post-kurapwa.Mamiriro epashure ekurapa kuchengetedza kupisa kwe2h pa60 ℃ uye kuchengetedza kupisa kwe2h pa120 ℃.

Jekiseni kuumba

Jekiseni molding inotora iyo granular zvinhu zvakagadzirirwa nekumisa polymerization, uye kuumbwa kunoitwa pane yakajairwa plunger kana screw jekiseni rekuumba muchina.Tafura 1 inoratidza yakajairika maitiro mamiriro e polymethylmethacrylate jekiseni molding.Process parameters sikuruu jekiseni kuumba muchina plunger jekiseni kuumba muchina dhiramu ℃ tembiricha kumashure 180-200 180-200 nepakati 190-230 kumberi 180-210 210-240 nozzle tembiricha ℃ 180-210 210-240 kuumbwa 4 jekiseni 0-80 ℃ 4 jekiseni 0-80 ℃ kudzvinyirirwa MPa 80-120 80-130 kubata kumanikidzwa MPa 40-60 40-60 screw speed rp.m-1 20-30 jekiseni zvigadzirwa zvinodawo post-kurapwa kubvisa kushushikana kwemukati, Kurapa kunoitwa mu70-80 ℃ kupisa kwemhepo kutenderera kuomesa ovheni.Nguva yekurapa ye acrylic bar kazhinji inotora inenge 4H zvichienderana nekukora kwechigadzirwa.

Thermoforming

Thermoforming maitiro ekugadzira plexiglass ndiro kana sheet kuita zvigadzirwa zvehukuru hwakasiyana uye maumbirwo.Iyo isina chinhu yakachekwa kuita saizi inodiwa inosungirirwa pafuremu yeforoma, ichidziiswa kuti ipfave, uye yobva yamanikidzwa kuti iite pedyo nepamusoro pevhu kuti iwane chimiro chakafanana nepamusoro peforoma.Mushure mekutonhora uye kuumbwa, mupendero unogadziriswa kuti uwane chigadzirwa.Iyo nzira yekudhirowa vacuum kana yakananga kudzvanywa kwe punch ine mbiri inogona kugamuchirwa yekumanikidza.Thermoforming tembiricha inogona kureva tembiricha inokurudzirwa muTebhurari 3. Paunenge uchishandisa nekukurumidza vacuum yakaderera dhizaini yekugadzira zvigadzirwa, zvakafanira kutora tembiricha iri pedyo neiyo yakaderera muganhu.Paunenge uchigadzira yakadzika dhizaini zvigadzirwa zvine chimiro chakaomarara, zvakafanira kutora tembiricha iri padyo nepamusoro muganhu.Kazhinji, tembiricha yakajairika inogamuchirwa.

Isu tine saizi yese yeArylic lens, kana uchivada, ndapota taura nesu nemutsa, isu tinogonawo kugadzira iyo Arylic lens sezvinodiwa zvako.Iwe unogona kutumira dhirowa kwatiri, saka, isu tinogona kukuitira ma mold.Ndinokutendai zvikuru.